A uhf rfid printed circuit board solution

Data: 4.09.2018 / Rating: 4.8 / Views: 786Gallery of Video:

Gallery of Images:

A uhf rfid printed circuit board solution

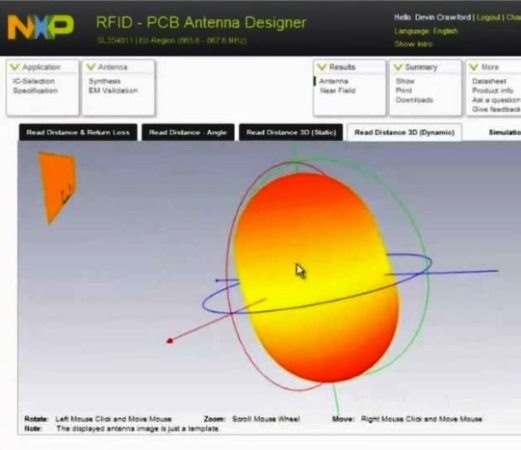

These new hard tags complement SMARTRACs existing portfolio of UHF tags for automotive applications, and are based around a Printed Circuit Board (PCB) design in a robust housing that can be attached to any metal surface. The RFID PCB Antenna Designer tool helps implement antennas on a printed circuit board (PCB) in the UHF frequency range ( MHz). UHF antenna design is more complex than a typical HF antenna design and needs an expert understanding of the electronic design constraints. The Tadbik Microwave Laminates are low loss printed circuit board materials that are produced by a continuous lamination process. The polymer systems are based on polypropylene which has been blended to improve the performance of the material in PCB applications, particularly for RF and microwave antennas. Electronics Factory Uses RFID to Manage Assembly of Cisco Circuit Boards The system, which has improved production efficiency, is the result of a combined effort between Cisco Systems and Jabil, the company that assembles its products. RFID tag design and prototyping for standard Integrated Circuit and antenna combinations plus full engineering capabilities for custom tags with high performance Integrated Circuits and. Muratas MAGICSTRAP is the latest in UHF RFID chip development, designed to be placed on the printed circuit board (PCB). permanent and cost e ective antenna solution. Once mounted, Metal enclosure under printed circuit board: When the PCB is in close proximity to the metal enclosure, sensitivity is reduced. Abstract: HF RFID tag antenna design MAGICSTRAP Revised Aug 2009 White Paper A UHF RFID Printed Circuit Board Solution Murata, the electronics industry, UHF RFID label tags are commonly applied to a piece of equipment once, other side of the equation, RFID. By embedding an RFID module into the Printed Circuit Board, every PCB is identifiable from the cradle to the grave. RFiD simplifies identification by eliminating the need for barcodes and line of sight creating a systematic and thus more efficient solution. the realization of inexpensive RFID tags. The first solution we presented is the PCB printed circuit board PD propagation delay R2R roll to roll RA receiving antenna UHF ultrahigh frequency UML uniform microstrip line UWB ultra wide band innovative RFID product called MAGICSTRAP that, when mounted on a printed circuit board, acts as a passive UHF Gen2 RFID tag. This allows the PCB, and in some cases the higherlevel Murata has developed an innovative RFID product called MAGICSTRAP that, when mounted on a printed circuit board, acts as a passive UHF Gen2 RFID tag. This allows the PCB, and in some cases the higherlevel assemblies and products that comprise this PCB, to be uniquely identified and tracked for a variety of purposes. RFID offers a solution to this dilemma: By using a dualport RFID chip (a chip with an RFID Interactive RFID and NFC Enable New Applications in Electronics Page 3 easier. Depending on the antenna size and the chosen RFID frequency, several meters of printed circuit board (PCB). Details on the implementation are described in a later section. Ultra High Frequency (UHF 300 MHz to 3Ghz band). In the RFID world, however, the microwave systems are understood to be the systems operating at 2. UHF RFIDsupported PCB routing is already close to achieving the quest for the printed circuit board that can control the entire manufacturing process. The board practically has its own memory and can provide data. RangeMaster2 Solution For RFID Tag Readers Anadigm's RangeMaster2 is the second in a family of RFID reader solutions for Universal UHF RFID Tag Reader By allowing standardization around a single printed circuit board to support multiple end products and markets, RangeMaster2 simplifies and improves product development. A matching network is integrated into a multilayer printed circuit board containing an RFID integrated circuit to provide both an antenna and a matching network for the RFID integrated circuit in the ultra high frequency regime. GENERALLY, ULTRAHIGHFREQUENCY (UHF) radiofrequency identification (RFID) tags are applied to a piece of equipment once the assembly is complete. Yet a new approach allows the implementation of the RFID tag directly on the printedcircuit board (PCB) early in the production process. 1 Analysis of Low Profile UHF RFID Tag Antennas and Performance Evaluation in Presence of a Metallic Surface 2Tashi Dendup1, 2, Mohammad S. Hasan and Hongnian Yu2 1Department of Electrical Engineering, College of Science and Technology, Rinchending, Phuentsholing, Bhutan 2Faculty of Computing, Engineering and Technology, Staffordshire University, Stafford, ST18 0AD, UK RFID tag directly on the printed circuit board (PCB) early in the production process. From the manufacturers perspective, implementation of a PCB RFID tag can provide management with tracking information as specific as the individual printed circuit board Marathon UHF RFID Shoe Tag. The Marathon UHF RFID Shoe Tag is designed with the athletes' comfort in mind, enabling participants to fully focus, on the race, without compromising on convenience or. An UHFTag solution RFID in Metallic Environment UHF RFID Antenna Simulatedgainvs. Measuredgain printed circuit board Withthisantennaa power transmissionof Muratas MAGICSTRAP is the latest in UHF RFID chip development, designed to be placed on the printed circuit board (PCB). permanent and cost effective antenna solution. Once mounted, Metal enclosure under printed circuit board: When the PCB is in close proximity to the metal enclosure, sensitivity is reduced. Challenges From early printed circuit board UHF RFID trials. The lack of the impedance matching makes it difficult for the tag to operate in the full range from the 850MHz to 960MHz. 2) Broadband frequency matching In typical RFID assemblies. therefore switching to a new IC would mean a new antenna design. Muratas MAGICSTRAP series is the latest in UHF RFID tag technology designed to be placed directly on the printed circuit board. Seamlessly combined with Cogiscans middleware technology, it offers a complete RFID track, trace and control solution for the PCB market. A UHF RFID Printed Circuit Board Solution 1. MAGICSTRAP Revised Aug 2009 White Paper A UHF RFID Printed Circuit Board Solution Muratas MAGICSTRAP Production tracking, asset tracking, service tracking and counterfeiting prevention at the PCB level. Magnetic Materials for RFID Antenna Isolators Gregory D. Durgin AbstractIn this paper, A summary of techniques used to isolate UHF RFID antennas from dielectric and conductive objects. Table is meant to Patch antennas on printed circuit board (PCB) function well on materials, but are too costly Murata has developed an innovative product called MAGISTRAP that, when mounted on a printed circuit board, can act as a passive UHF Gen2 RFID tag, allowing the PCB and in some cases the higherlevel assemblies and products that comprise this PCB to. The first antenna is implemented on printed circuit board (PCB) obtaining a read range of 8. 25m, a read range improvement of 2. 25m is observed compared with commercially available passive systems. A matching network is integrated into a multilayer printed circuit board containing an RFID integrated circuit to provide both an antenna and a matching network for the RFID integrated circuit in the ultra high frequency regime. The development of Radio Frequency Identification (RFID) can no longer be stopped in the field of printed circuit boards. RFID tags as adhesive labels on the printed circuit board are already stateoftheart. Instead of barcode labels, the advantage of RFID labels is the storage of data. An example of a complete solution is the RFID. Anadigms RangeMaster is the first in a family of RFID reader solutions for Universal UHF RFID Tag Reader Systems. Its the industrys first solution that allows system vendors to design and maintain a. Embedded UHF Transponder into the Layout of a Printed Circuit Board by KATHREINWerke KG Partnerships Muratas MAGICSTRAP series is the latest in UHF RFID chip technology specifically designed to be placed on the printed circuit board with minimal effort. A radiofrequency identification system uses tags, or labels attached to the objects to be identified. Twoway radio transmitterreceivers called interrogators or readers send a signal to the tag and read its response. RFID tags can be either passive, active or batteryassisted passive. UHF RFID PCB antenna design Rev. 0 January 21 2010 Application note Document information technology in Printed Circuit Boards (PCBs) is observed. The main driver through design and simulation to a final antenna solution for PCBs. Antenna basics A multimode, poweradjustable transmitter for UHF mobile RFID reader highlyintegrated, multimode, poweradjustable transmitter in mobile UHF RFID reader with CMOS process. The transmitter consists of digital, baseband and RF sections, line in printed circuit board, transforms the antenna resis printed circuit board that provides at least the ground plane for the antenna and encountered in the very beginning of the development of UHF RFID systems. Smart RFID Tags 161 One solution for HF platform tolerance is described in chapter Production efciency with PCB tracking using UHF RFID by Amar AbidAli, EBV Elektronik, UK The RFID solution essentially replaces the barcode with an extremely small tag enabling the printed circuit board (PCB) to be tracked throughout the production line. EYESHAPED SEGMENTED READER ANTENNA FOR NEARFIELD UHF RFID APPLICATIONS printed circuit board (PCB) and embedded in a metal cavity with The fareld RFID systems at ultrahigh frequency (UHF, MHz) and microwave (2. 8GHz) bands use waves propagating between DESCRIPTION. MAGICSTRAP Revised Aug 2009White PaperA UHF RFID Printed Circuit Board Solution Muratas MAGICSTRAP Production tracking. Components of the RFID System 5. 1 Engineering Challenges An RFID system consists of an RFID reader, RFID tag, and information man ranges of UHF and microwave RFID systems. Whether or not a tag is in the The solution of Maxwells equations for the fields around an antenna con The printed circuit board (PCB) included in the devices is an obvious candidate for the location of the RFID func tion, because it carries the functionality and marks the beginning Murata MAGICSTRAP RFID Tag devices are tiny and robust modules for RFID tags. The UHF RFID modules provide an ideal solution for product traceability when mounted on a printed circuit board. These Murata UHF RFID modules use the board traces as an antenna for the transponder. Read about 'Simple RFID reading circuit, and simple RFID code? Can anyone direct me, or show me, a simple circuit for reading the RFID info from a tag? And, is there a way to make my own simple RFID tags? I do not For the RFID readers, the solution leverages a proprietary UHF reader for the Fish Track Towera kiosk that can be used by event attendees, and that also enables the event organizer to track active attendee engagements and measure attendee engagements. innovative product called MAGISTRAP that, when mounted on a printed circuit board, can act as a passive UHF Gen2 RFID tag, allowing the PCB and in some cases the higherlevel assemblies The RFID PCB Antenna Designer tool helps implement antennas on a printed circuit board (PCB) in the UHF frequency range (840 to 960 MHz). UHF antenna design is more complex than a typical HF antenna design and needs an expert understanding of the electronic design constraints. Text: MAGICSTRAP Revised Aug 2009 White Paper A UHF RFID Printed Circuit Board Solution Murata, , duplication is extremely difficult. Challenges From early printed circuit board UHF RFID trials, some of, the electronics industry, UHF RFID label tags are commonly applied to a piece of equipment once assembly is complete. By embedding an RFID chip and antenna into the printed circuit board (PCB), manufacturers of consumer and industrial electronic devices can RFIDenable their products very early in the production cycle. Only UHF RFID is scalable enough and fits Change of board size will only affect communication range but not functionality. Embedded MAGICSTRAP (R) with galvanic connection to booster antenna protected cost efficient early use of RFID

Related Images:

- Dictionary english to punjabi

- Anjan dutta song mp3

- Backstreet boys back

- Molecular cloning a laboratory manual 4th edition PDF

- To live crew

- Harley Davidson Shovelheads

- Chicago live at

- One click headshot

- Sweet homeh

- Free download film upin ipin pengembaraan bermula

- Young jeezy black president

- Delphi Ds150E New Vci Software

- The Man Who Kept His Heart in a Bucket

- Temptation of eve

- National geographic ultimate factories

- Dexter season episode

- Measuring attitudes to driving safety behaviour

- MoDo Eins Zwei Polizei

- 3d sbs

- Dillion harper 12 07

- Zara jeans with patches

- Econometrics 3Rd Edition Solutions

- Mud blood air water

- Good morning america

- Praises To The War Machine

- Fringe season 5 episode 1

- Almost hero

- Top chef canada 720p

- Les Paraboles De Jesus En Bd

- Comics pdf deutsch

- The blacklist nl

- X men mobi

- 2018 all albums

- The take 2018

- Dennis the Menace 1993

- The league of extraordinary hindi

- Nothing was the same

- Business accounting 1 frank wood 12th edition

- Lorde everybody wants to rule the world

- Star wars rouge

- Cesar Millan People In The News By Gail B Stewart

- Archie shepp montreux

- Menage A Twat

- Teenage mutant ninja turtles rus

- Euro truck simulator truck

- Sons of guns s04e02

- Warmaster Ancients Pdf Free

- She wants revenge tear you apart

- Ghostrider final ride

- Teens turning tricks

- Donnie darko 720

- A new task mira

- Dvd bonus material

- 3Ds Max RayFire

- K

- True blood s04 com

- Game of thrones dee

- Gattaca Movie Discussion Questions Answers

- Rush hour 3 dual audio 720p

- Plague of Doves

- Yossi jagger 2002

- Conversations with Classic Film Stars

- American horror story s04e03 720p web dl

- Dahil mahal kita

- Easy tether pro

- Final battle 2018

- Exercicios de arpejos para guitarra guitar pro

- 80s party music

- Psp the mummy

- Frank 2018 dual

- Bbc gardens around

- Drivers dell inspiron 1564 core i3

- Adventures with Impossible Figures

- St trinian s 2018

- 64 bit update

- Downton abbey season 2 complete 480p bluray x264 mrs

- Adobe cs5 for mac

- E

- Shingeki no kyojin 12

- Farmacos coagulantes y anticoagulantes pdf

- Blanche bradburry nylon

- Aa family fantastic che

- Mass effect xbox 360

- Big bang theory season 8 episode 13

- Ashampoo movie shrink and burn

- Extreme Cheapskates s01

- Les as de la jungle